Screen printing is actually fun and relaxing at the same time. The hardest part is getting an order from the customer. After that the next hardest part is not getting paint all over myself! It all starts with an awesome bunch of suppliers, an understanding UPS man and a bit of time receiving and sorting. It looks like this when I get a delivery…

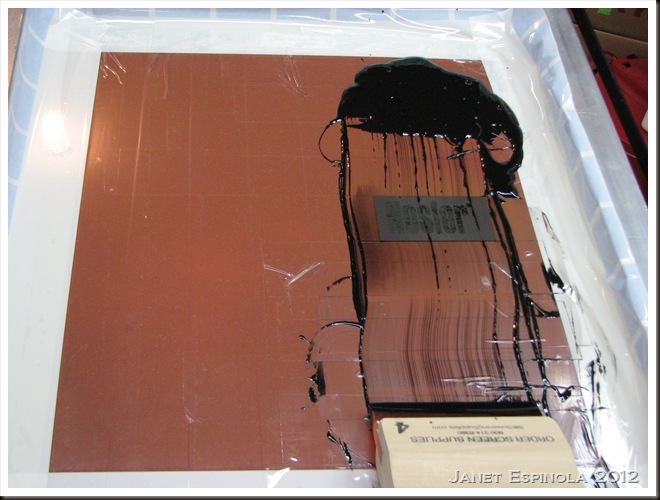

The screens must be cured with film and then the design is burned in. I tape the screen off just to aid in the clean up process later and then I add the ink. In this case, I am imprinting a left chest logo with black ink.

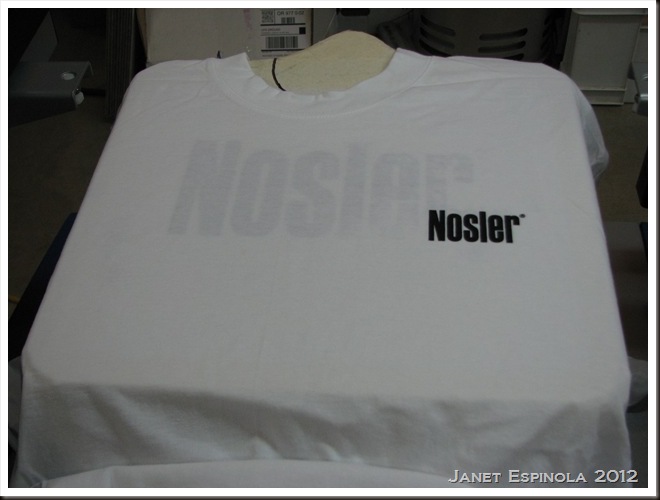

The screen is placed onto the printer station where everything has been aligned to print in the correct area of the garment. Here is the way it appears when in production when I am imprinting…

And this is my view as the printer. You can see the ink stained into the platen from the back imprint I completed on the shirts first.

After the imprint is completed the shirt goes under a heater to cure the ink.

When all of the apparel is completed (front & back) it is folded, counted and placed in the boxes to get ready for delivery.

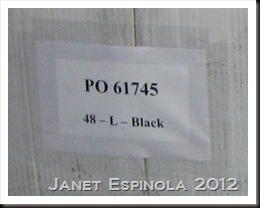

The product is counted and the boxes are sealed and labeled.

An invoice is prepared as well as a receiver. The boxes are loaded and the delivery is made. Customers always like receiving their orders early so we try to always deliver early.

We specialize in smaller orders and we deliver. We would be thrilled to do your next printing job.